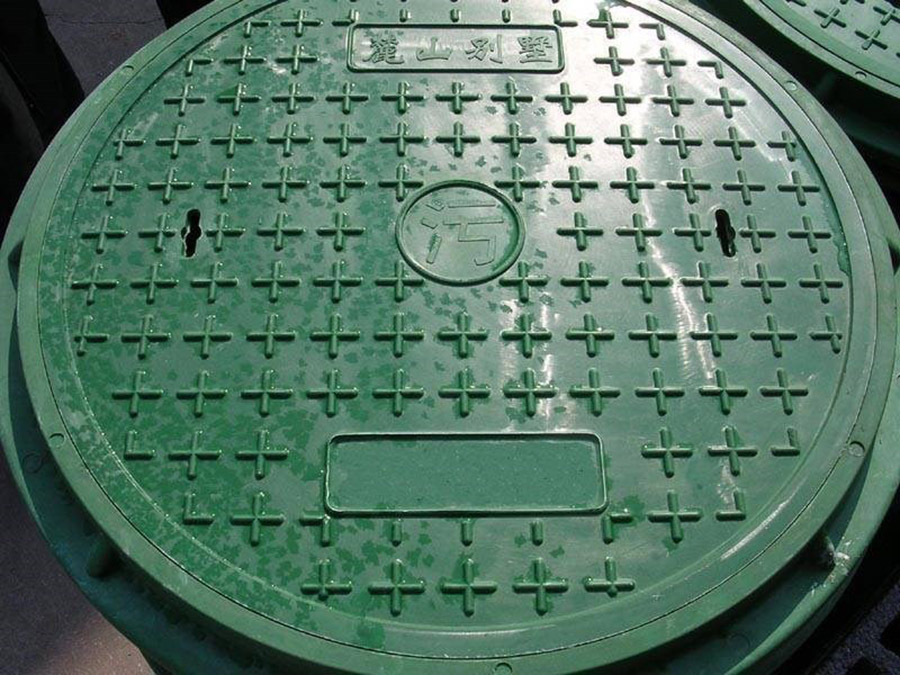

Manholes are important construction elements are they are multifunctional. They let the maintenance guys to access the underground piping and telecom lines under the road. They can also access the meters that measure the liquid flow in the sewer lines. But, these manholes need to be covered so that a person crossing the road may not fall into it accidentally. These covers are also important as they run smoothly on roads.

These covers are available in a lot of designs and materials having their own pros and cons. Apart from the dimensions of the cover, the material used to make them is of an utmost importance. The material of the cover helps in determining how much load the cover can tolerate and if it can stand the test of time. Today, composite manhole covers are famous because of its high load ability and durability. Here are the types of composite or plastic manholes covers used today.

- FRP or GRP manhole covers

FRP stands for fiber reinforced plastic which is the best composite material to make manhole covers. It consists of elements like unsaturated polyester resin, quartz, glass fiber, and two types of additives. The process of manufacturing them is quick and complex when comparing to BMC or SMC covers. The FRP manhole bears a good surface, are wear and tear proof and has a huge load ability.

- BMC manhole covers

BMC stands for bulk molding compound which is a type of composite material used for making BMC covers. The elements which are used for making these covers are glass fiber, unsaturated polyester resigns, trasys, calcium carbonate, and steel bars. The process of making such covers is quite simple and doesn’t cost you much. The benefits of BMC covers is that they bear a smooth surface and a uniform color which is similar to plastic. But the load ability of these covers is on the lower side and they are prone to friction as well.

- SMC manhole covers

SMC stands for sheet molding compound which is used for synthesis of SMC covers. The elements used for making these covers are glass fiber, unsaturated polyester resins, trasys, calcium carbonate, and a tiny amount of additive. The process of making these covers is a tad bit complex than BMC covers and is costly. SMC bears a smooth surface and has a better load ability. But they are also prone to friction.